Welcome to the first of many blog posts focused on Engineering here at Vapor IO!

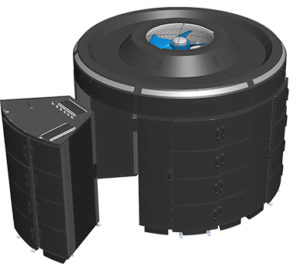

We’ll to start with a post about the Vapor Chambers. Besides being an amazing accomplishment in engineering, a true implementation of an all-in-one automated rack and enclosure system, and one of the cornerstones of our Kinetic Edge solution…we often get asked if they “really exist” and “can we see one?”. Yes and yes! However, before we get to the proof, let’s first briefly review the Chamber itself.

Engineered for the Future

The Vapor Chamber is a patented cylindrical rack and enclosure system rated to house 150 kW of IT equipment for stable, long-term operation. That means operators can deploy upwards of 15,000 CPU cores in a 2.88 m (9.45-foot) diameter footprint. The unique shape and airflow design of the Vapor Chamber makes it possible for data center operators to deploy an unprecedented level of compute and data storage resources in a cost- and space-efficient way, in a variety of locations, including both traditional and edge data center locations. The Vapor Chamber allows data centers to deploy at higher-densities and lower operating costs than beyond the capabilities of traditional IT equipment racks that rely on raised floors and cold and hot aisles. Traditional rectangular rack designs suffer from many problems, including low density (6-12 kW per rack), air re-circulation problems (particularly at the bottom of the rack), air pressure mismatches and uneven cooling, impacting the long-term reliability of the IT equipment. The unique system design of the Vapor Chamber addresses all of these issues, enabling hyperscale-like densities through superior air handling and evenly-distributed cooling. at the edge.

The Vapor Chamber is ideally suited for environments that require support for multiple tenants on the same infrastructure, including traditional data center colocation as well as for edge data centers, which will require shared infrastructure to be economically viable. To support multitenancy the Vapor Chamber provides physical separation between tenants, with up to 24 tenants per Chamber. Each tenant is provided access to only their IT equipment, fiber and power. The innovative and secure Vapor Wedge Security Zones provide electronic and physical access control, isolating tenants from each other to ensure uninterrupted operation. The Vapor Chamber also includes Vapor IO software for autonomic operation, remote lights-out monitoring and programmatic API-driven control.

Designed to Live on the Edge

The Vapor Chamber can be deployed in a number of different environments. These include standard data center environments but also non-standard office or retail space, or remote outdoor enclosures such as equipment sheds at the base of cell towers, without the need for special cooling systems.

In particular, edge computing deployments present new challenges for data center design and use, as they are often in remote locations (such as at the base of a cell tower) where space is at a premium for one or multiple tenants, and the operator is often repurposing a structure or space that wasn’t designed to be a data center. The unique combination of innovative hardware and software in the Vapor Chamber makes it the foundation of a dense, distributed and remotely-operable data center infrastructure needed to power the edge.

This is made possible by the Vapor Chamber’s unique airflow design which uses a built-in Central Exhaust Cell (CEC) as a heat-evacuation chimney, rather than relying on a traditional hot and cold aisle approach to the data center. This unique configuration of the Vapor Chamber makes it more efficient than other alternatives, and also easier to deploy.

Although it does not remove the need for climate control, the Chamber can operate with a higher input air temperature than traditional rack and enclosure systems, lowering the cost and difficulty of climate control for the HVAC.

The Upper Chamber houses the central exhaust fan and serves as an area for cable management. In a typical indoor deployment, a hot-air chimney connects from the top of the Upper Chamber to a return air plenum in the datacenter sub-ceiling. The chimney fully contains the hot exhaust from the Vapor Chamber and ensures it does not recirculate to the equipment. Incoming power cables travel along the exterior of the chimney and into the top of each Wedge Rack to power IT equipment within the Chamber. The Upper Chamber contains sensors for monitoring exhaust air temperature and airflow. Software running within the Chamber uses data from these sensors and others throughout the Chamber to dynamically control the speed of the 91.4 cm (36”) central fan, ensuring optimal airflow for IT equipment and safe operation.

The Vapor Chamber has three distinct sections:

- CEC: The central exhaust cell around which the Chamber is arranged. Acts as a hot air exhaust chimney and ensures consistent airflow throughout the chamber. A variably-perforated wall separates the CEC from the rear portion of the IT equipment in each Wedge Rack. The carefully-engineered perforations of the CEC allow optimal airflow while maintaining neutral static pressure, which is key to achieving a sufficient supply of air and consistent heat evacuation from the Vapor Chamber. The design of the CEC allows the Vapor Chamber to operate safely with higher densities of IT equipment compared to a traditional rack and enclosure system, even with a higher inlet air temperature. Combined with the rest of the Vapor Chamber design, the CEC eliminates the need for the traditional hot and cold aisle approach to data center airflow.

- Upper Chamber: Houses the central exhaust fan and provides space for cable management. It also incorporates sensors and the LED light ring around the top of the Upper Chamber, comprised of six individual bars, one above each Wedge Rack. These bright and color-rich LED light bars can be programmatically configured to display millions of color combinations in a blinking or solid fashion. The LED light ring is a visual indicator that turns on in response to a range of user-programmed events.

- Lower Chamber: Consists of six Wedge Racks and a Leveling Base. Serves as the foundation of the Vapor Chamber and provides support for the other sections that integrate to form the Chamber. The Wedge Rack design makes it easy to service equipment from the front or the back of the rack. Each Wedge Rack has quick-disconnects for power and network, making it easy to remove each rack for maintenance and service independent of other racks in the Vapor Chamber. To access the rear of IT equipment in a rack, a technician may easily roll the rack out of the Leveling Base. The Leveling Base maintains the contact between the Vapor Chamber and the floor, and with its unique design, allows for opertion on uneven floors. The Chamber and its Leveling Base will also distribute the weight of any installed IT equipment, which minimizes the point loads on the floor from densely-filled racks in order to accommodate a wide range of surfaces, IT equipment and support structures

Intelligence Built In

The Vapor Chamber incorporates over 92 sensors to monitor and tune its airflow to maximum efficiency, as well as to report real-time status to a remote operations center. The sensors connect to the Vapor Edge Controllers (VECs) in each Wedge Rack. The VECs run sophisticated software for local monitoring, Chamber control, and optimization. All of the sensor data is available to external services via a web API, allowing remote management and monitoring as well as aggregation of data across multiple Chambers and multiple sites.

Temperature sensors are installed between the Upper Chamber and Lower Chamber, and along the entire height of each Wedge Rack to provide a real-time view of the thermal characteristics and status of the Chamber. The sensors in the Upper Chamber monitor the exhaust air from the CEC. An ambient room temperature sensor located on the outside of the Chamber and the temperature sensors along the height of each rack provide detailed data about the temperature of inlet air entering the Chamber from the room as well as the temperature differentials between the fronts of the racks to the backs. Temperature information from sensors integrated into the motherboards of servers that provide data via supported monitoring protocols, such as IPMI, can optionally be used by the VEC, if desired by tenants.

A sensor in the Upper Chamber monitors the speed of exhaust air movement from the CEC. In addition, differential pressure sensors throughout the Lower Chamber provide a way to compare the air pressure at the front of each Wedge Rack to that between the rear of the Wedge Rack and the CEC wall. These pressure readings allow software on the VEC to adjust the fan speed to maintain optimal airflow by equalizing to neutral pressure.

Other sensors are present throughout the Vapor Chamber to measure air humidity and other conditions. These sensors provide visibility into detrimental operating conditions which may develop and, if left unchecked, could result in damage to IT equipment within the Chamber or other undesirable consequences. Any combination of sensor readings can be used by the VEC software to trigger user-programmable actions autonomically.

Within each of the six Wedge Racks of a Vapor Chamber is a VEC. These VECs control the operation of the Chamber by running software which provides detailed telemetry data from the sensors throughout the Chamber. A web-based API is used to access this data. All VECs within the Chamber run as a six-node cluster, and use Kubernetes for container orchestration, management, and fault-tolerance (Don’t worry…we’ll cover this in a later post). Each VEC is a device positioned in the left side of its Wedge Rack, inside the Secure Facility Zone in a Chamber configured for multi tenancy. This limits physical access to the VEC to the Chamber owner or facilities team, as each VEC is responsible for all of the tenants within a Wedge Rack.

Time for the Show!

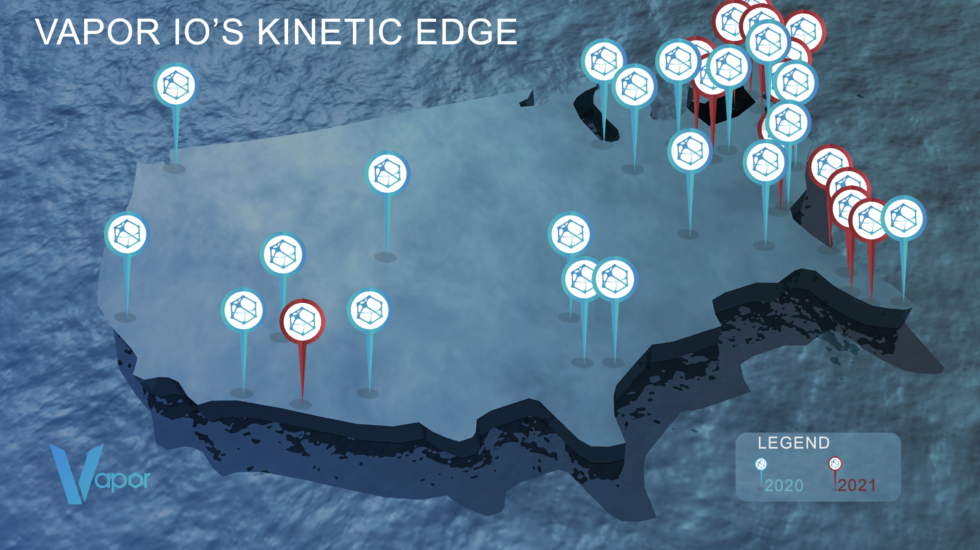

Instead of posting a bunch of pictures of Vapor Chambers in the wild, we decided video would add a bit more validity. What follows is a video (looks best full screen) that shows one of two Vapor Chambers currently deployed in equipment rooms at the base of two different mobile phone towers in Chicago, IL. Utilizing the Vapor Edge Portal (we’ll also cover this in a later post), you will see us manipulate the LED ring remotely from our headquarters in Austin, TX. FYI, this is the same Chamber shown in the header picture of this blog post. Enjoy the video and stay tuned for our next post!