Home / Technology / Modular Data Centers

Vapor IO’s Kinetic Grid architecture is the unique combination of high-speed software-defined networking, edge colocation and edge exchange — all pre-integrated into a single package from a single supplier—lowering the cost and complexity of edge computing.

The VEM-20 is a high density outdoor pedestal solution for the deployment of edge applications. Unlike many telecom pedestal solutions, the VEM-20 is designed with data center operators in mind and provides solutions and features commonly found in enterprise data centers. The VEM-20 offers two physically and logically isolated 10 kW racks.

The VEM-20 has also been specifically designed to support 5G O-RAN, serving as many as 20 towers from each pedestal. A set of carefully-located VEM-20s become an ideal platform on which to build a virtualized 5G network and serve it with local breakout, exchange and edge compute applications.

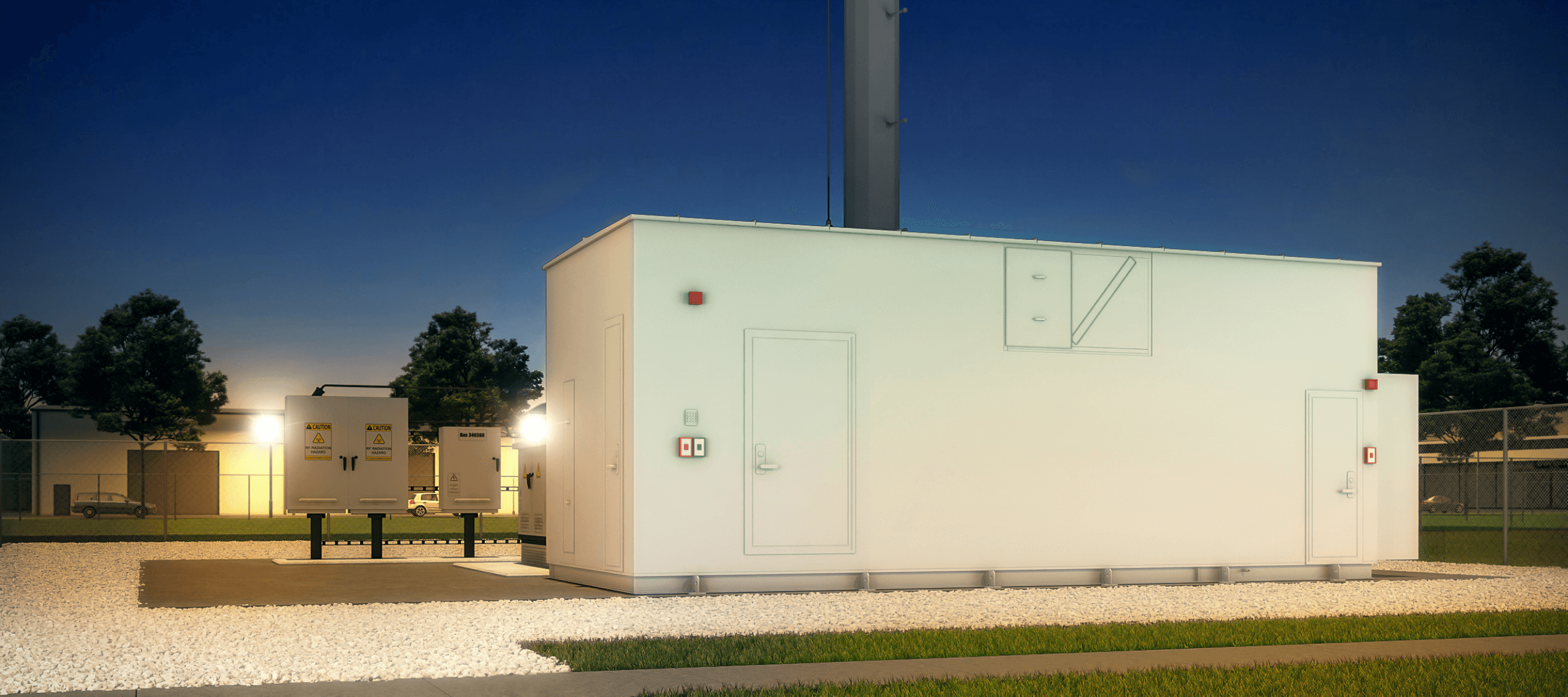

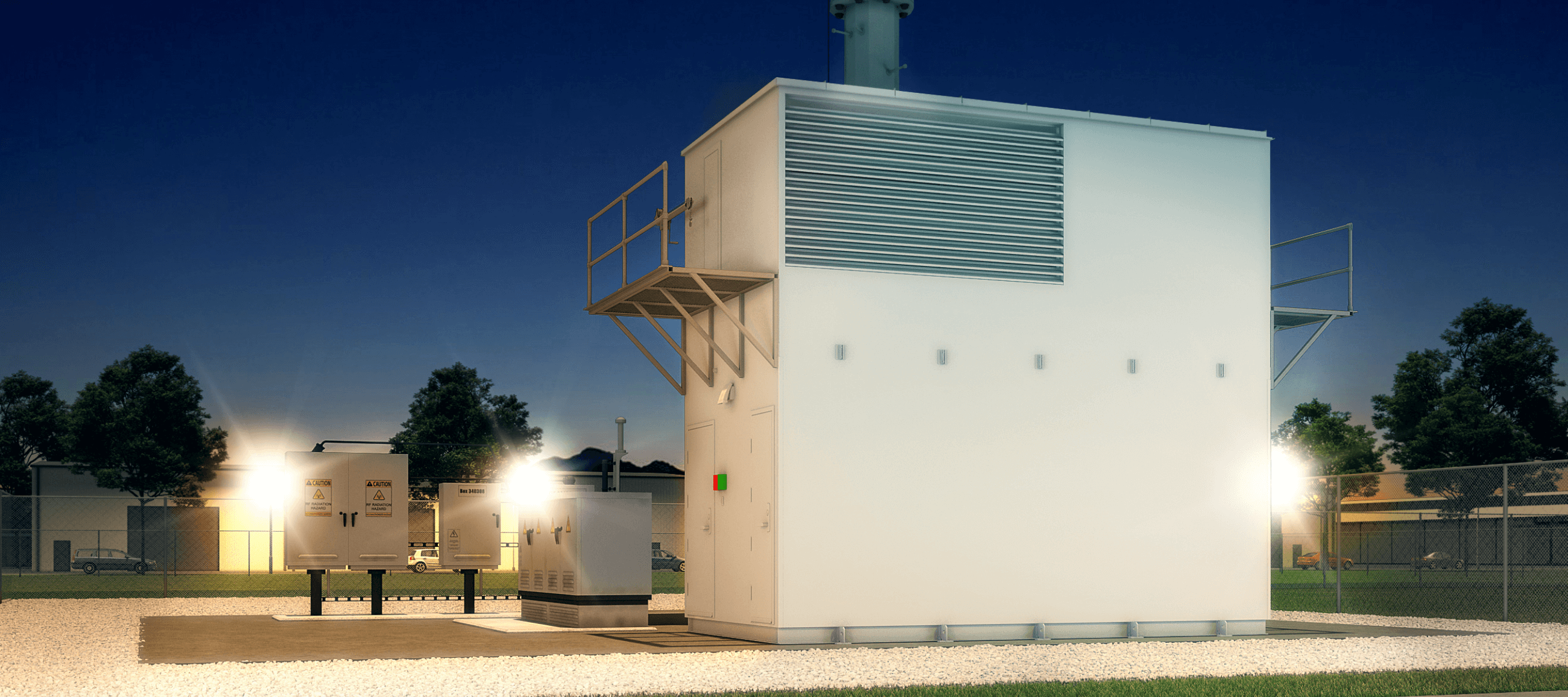

Capable of supporting 150 kW of IT equipment, the VEM-150 is slightly larger than a standard cargo container and has six 36 kW high-density racks that can support up to 24 individual tenants with locking and isolation mechanisms on every quarter rack. The VEM-150 exists in a few locations, but has been replaced by the VEM-180 for new deployments.

The VEM-180 is a two-story stacked system capable of housing 180 kW of IT equipment with separate tenants in each of 8 or 10 racks, depending on the model. The VEM-180 has replaced the VEM-150 for new deployments.

The State of the Edge report is the go-to resource to understand edge computing in the industry today, and is created by experts in the field. Covering edge computing terminology, architecture, technologies, applications and futures, don’t miss your chance to read it now.

6200 Bridgepoint Parkway, Building Four,

Ste. 250, Austin, TX 78730

1-888-477-6660

We will reach you with your email address soon.

Thank you for the time!